PP FIBER PRODUCTION LINE Manufacturing of filament yarns YouTube

Polypropylene Yarn Manufacturing From Pellets to Yarn Geotextile

Polypropylene yarn is also recognized as PP, and Polypropylene yarn is known to be the lightest and most functioning yarn in the textile business.. Understanding the Manufacturing Process of PPGL Sheets . January 5, 2024 . Exploring the Different Types of PP Sheets and Their Properties . January 4, 2024 . Bio-Medical Waste Disposal Bags.

Production of polypropylene yarn Karat

Polypropylene multifilament yarn, often referred to as PP yarn, is a versatile textile material with a wide range of applications. This article will take you behind the scenes to explore the intricate process of manufacturing PP multifilament yarn and understand the key steps involved in its production. The Basics of PP Multifilament Yarn PP multifilament yarn is a type of textile yarn made.

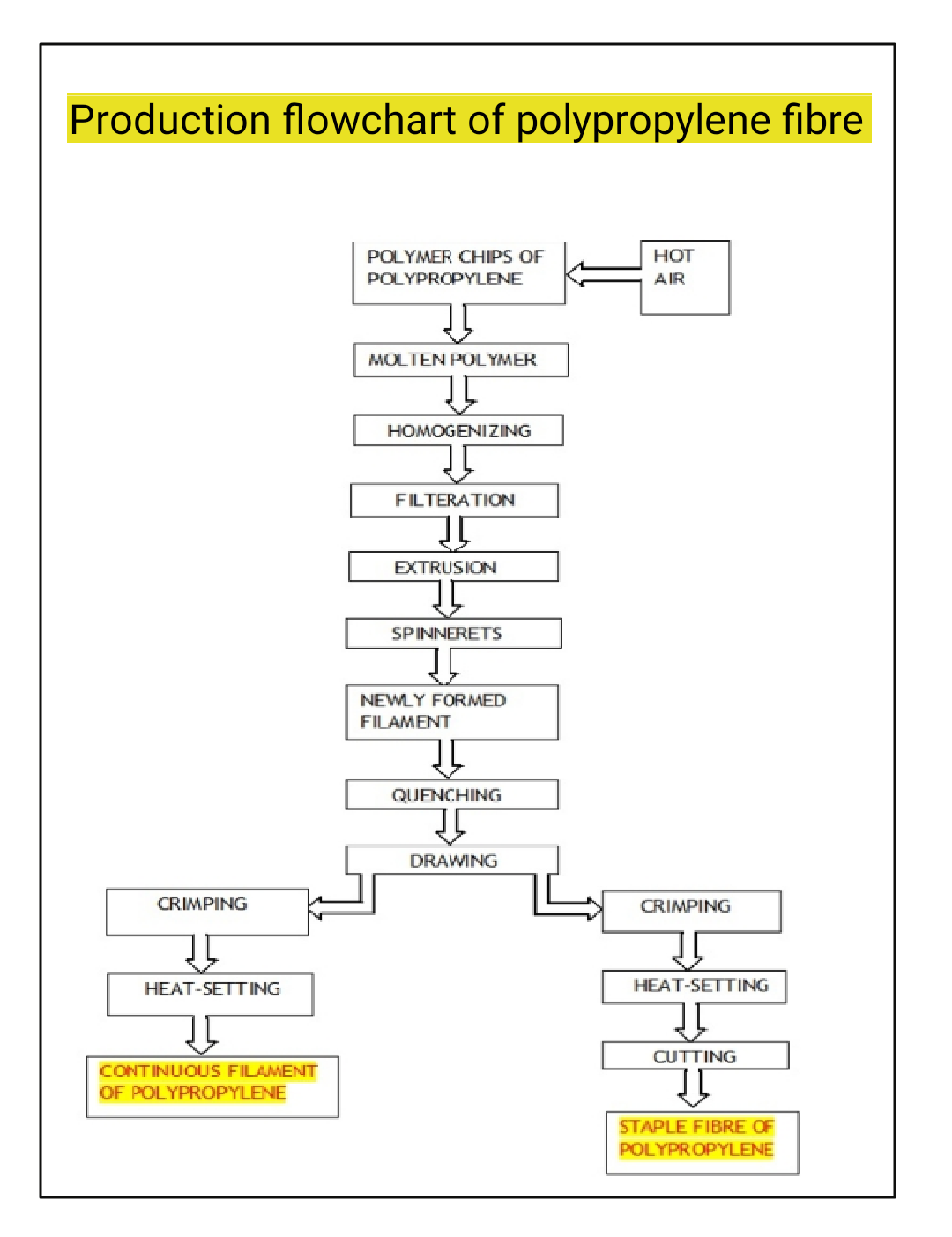

Textile Adviser PRODUCTION OF POLYPROPYLENE FIBRE

godets either as a two-step process (spin process separated from the draw process) or one-step (spin process integrated with draw process) process. The most modern FDY manufacturing processes are one-step. In this case, yarn is passed over heated godets with their associated idler rolls and/or second godet and gets drawn between the sets.

High Speed PP Flat Yarn Making Machine TKGE1001000156H(FW350M

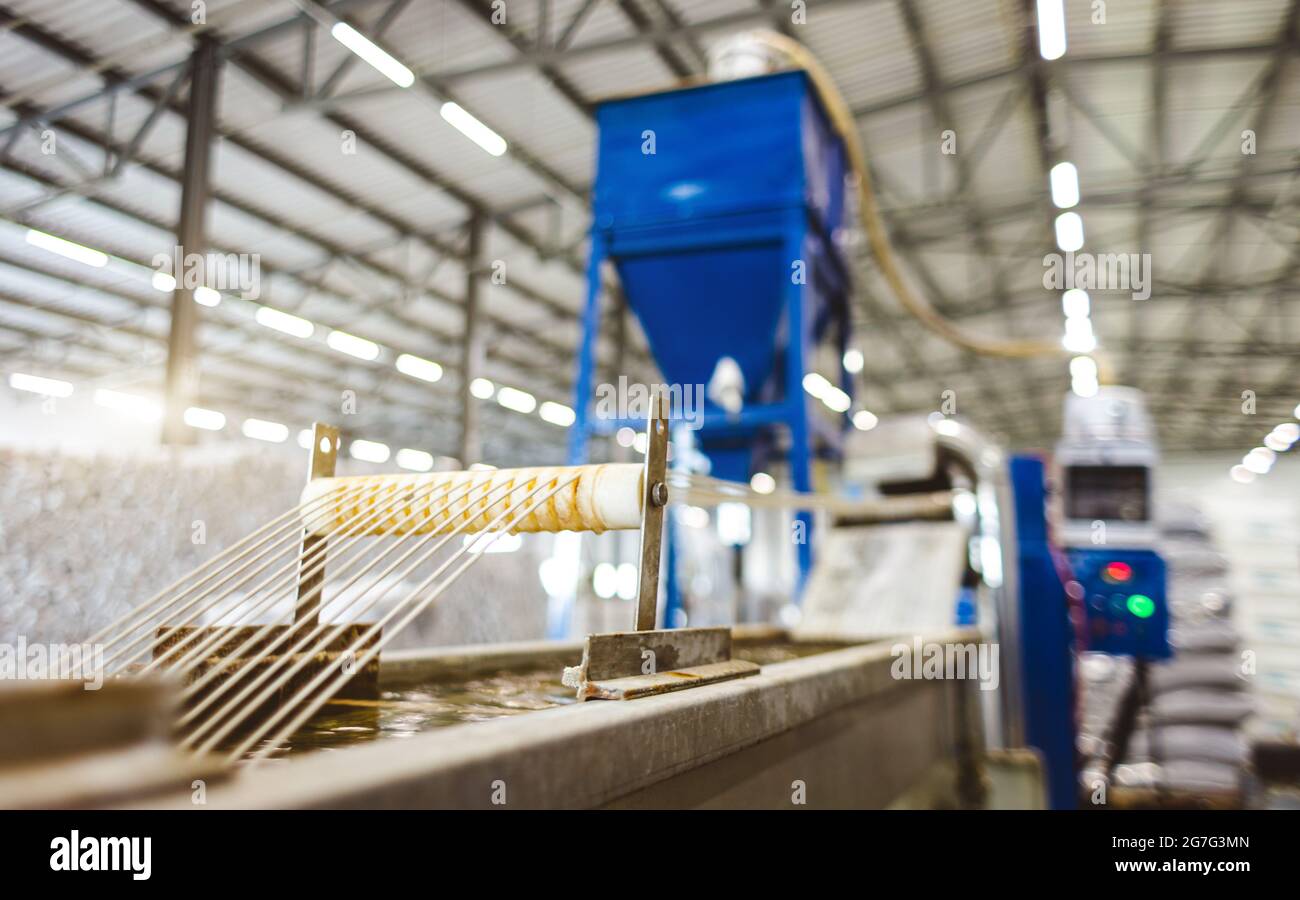

The polypropylene (PP) yarns with PTFE coating were obtained on the laboratory plant imitating the manufacturing process of production of polypropylene yarns from melt. It consists of two laboratory stands, their schemes are given on Fig. 1, Fig. 2: stand for spinning (SFPV-1) (Fig. 1) and stand for orientational stretching (OSV-1) of synthetic.

PP YARN MANUFACTURING PROCESS YouTube

Introduction Polypropylene multifilament yarn, often simply referred to as PP yarn, is a versatile material with a wide range of applications in various industries. From packaging to textiles, this strong and durable yarn plays a crucial role. In this comprehensive guide, we will take you through the journey of polypropylene multifilament yarn, from its manufacturing process to its end-use.

PP fabric Polypropylene Fabric Manufacturing Process Leading

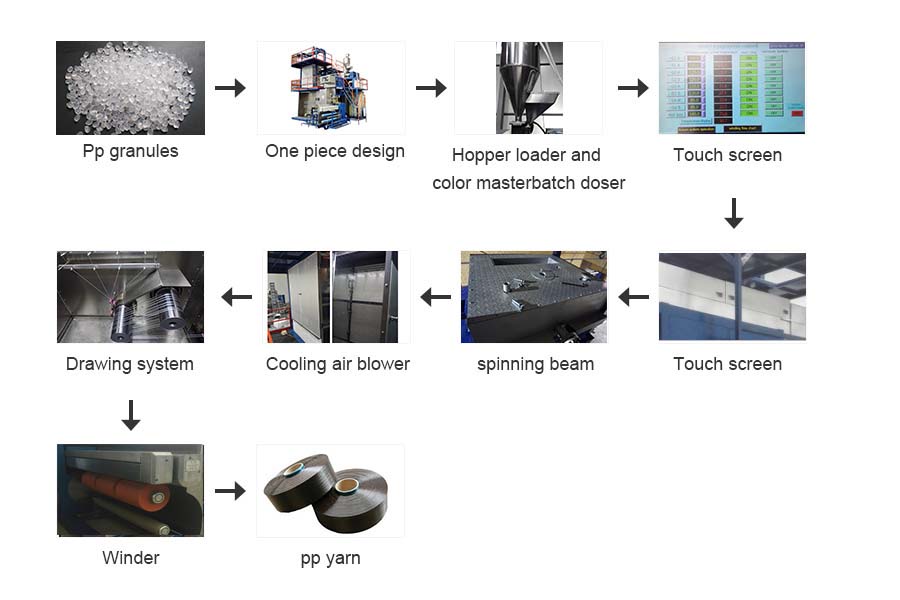

FDY PP multifilament yarn spinning machine. 1) Low power consumption, 1-1.2kw/1kg yarn . 2) Fast asscmble and trainning, professional engineer 10-15days . 3) Reasonable design to make high tenacity yarn 7-7.5g/d . 4) Easy operate, PLC control + touch screen . 5) It require the building roof 7m . 6) Electric parts from famous JAPAN brand

Premium Photo The technical process for the production of

The process of manufacturing PP woven bags involves mixing raw materials starting with PP or HDPE pellets and other additives, extruding the raw materials into a yarn PP resin is heated with feeler of CaCo3 and pigment, melted and extruded as a flat film. It is then slit into tape yarn by the slitting unit and stretched and annealed.

Production of polypropylene yarn Karat

Automation in Manufacturing Automation has streamlined the manufacturing process, reducing human error and increasing productivity. It ensures consistency and quality in every batch of polypropylene multifilament and PP yarn. Sustainability Efforts

PP FIBER PRODUCTION LINE Manufacturing of filament yarns YouTube

The polypropylene yarn (PP Yarn) produced by Shubham is further processed to form highly durable industrial bag clothing threads. These industrial threads are designed to match the international standards and are manufactured under strict supervision with highly advanced German technology needle looms, providing packaging solutions to a host of industries.

The Technical Process for the Production of Polypropylene Yarns for

A process and apparatus for producing multi filament yarn from polypropylene polymer. The process includes the steps of spinning an undrawn yarn using a spinnerette, and winding the.

FDY PP multifilament yarn spinning machine, fdy yarn manufacturing

The process of manufacturing PP woven bags involves mixing raw materials starting with PP pellets and other additives, extruding the raw materials into a yarn PP resin is heated with feeler of CaCo3 and pigment, melted and extruded as a flat film. It is then slit into tape yarn by the slitting unit and stretched and annealed.

FDY PP multifilament yarn spinning machine, fdy yarn manufacturing

What is PP Multifilament Yarn? PP Multi-filament yarn is one of the most fundamental pieces of the bundling business. It is produced utilizing strings, and these strings are known as fibers. The stories are turned on machines after the thread is expelled. The measurement of the strings in the multifilament experience is tiny.

The Technical Process for the Production of Polypropylene Yarns for

This paper reports on the environmental issues associated with the manufacturing of a new insulation material (panel) produced with fibers from Eucalyptus bark. The analyses consider four types of eucalyptus bark panels with different bulk densities (25, 50, 75 and 100 kg/m 3).For each type of panel, the environmental impact assessment is performed using Life Cycle Assessment (LCA) methodology.

AN OVERVIEW OF POLYPROPYLENE YARN INDUSTRY Shubham Polyspin

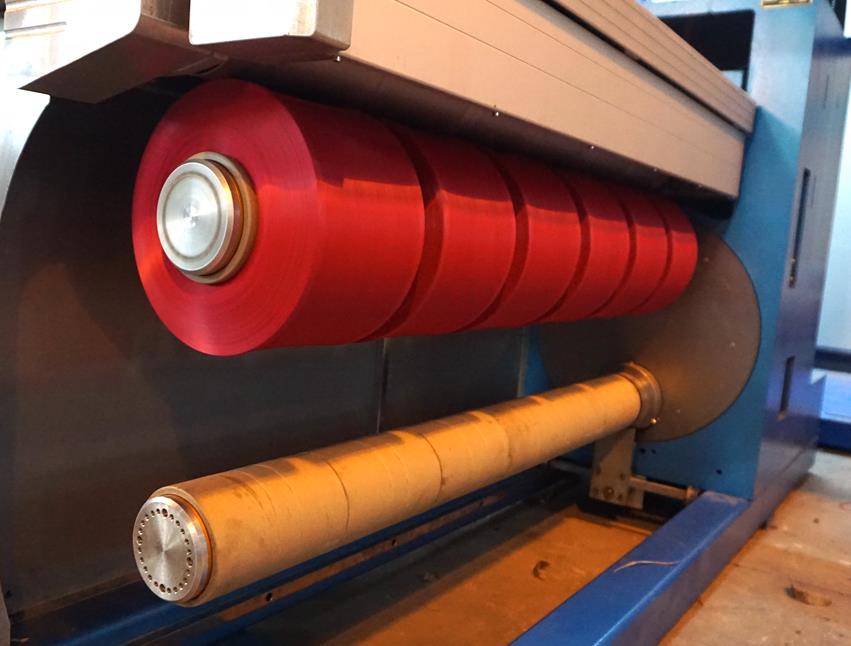

The principle behind manufacturing a thread is always the same: spinning pumps press the polymer melt through micro-fine spinnerets under extremely high pressure. The filaments created are then bundled into threads, drawn over godets and wound using a winder. Precision processes for textile yarns

Production of Polypropylene Yarn for Making Bags Stock Photo Image of

A study on manufacturing units of Polypropylene Woven fabric was taken up to obtain information regarding various aspects of Polypropylene packaging material such as products covered, setup of units, raw materials, manufacturing process and future plans.

The technical process for the production of polypropylene yarns for

Polypropylene (PP) is a thermoplastic "addition polymer" made from the combination of propylene monomers. It is used in a variety of applications to include packaging for consumer products,.